Electricity network data – bringing together asset position and condition

To operate effectively, electricity networks collect and manage data concerning the asset’s position (such as OHL clearances or vegetation encroachments) and asset condition (such as damage or degradation of safety notices or insulators). This data has traditionally been collected using foot patrols to assess each pole or tower. Although a tried and tested approach, it takes time, a lot of man power and has a high operational cost.

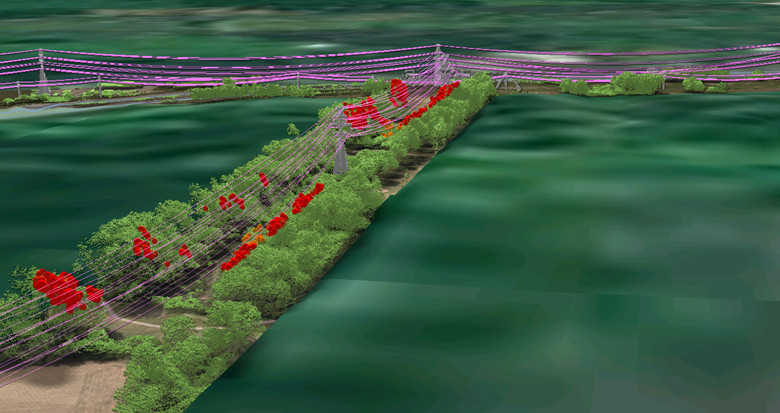

In recent years we have seen a move towards using technology to collect some of the asset data that would previously have been acquired when walking the line. Driven by a need to increase efficiency in vegetation management, techniques such as airborne surveys using cameras and laser scanners have been used to provide accurate data for the network environment. Delivering spatial reports and statistics from 3D datasets is an approach commonly used by Transmission Network Operators and becoming increasingly more common with Distribution Network Operators.

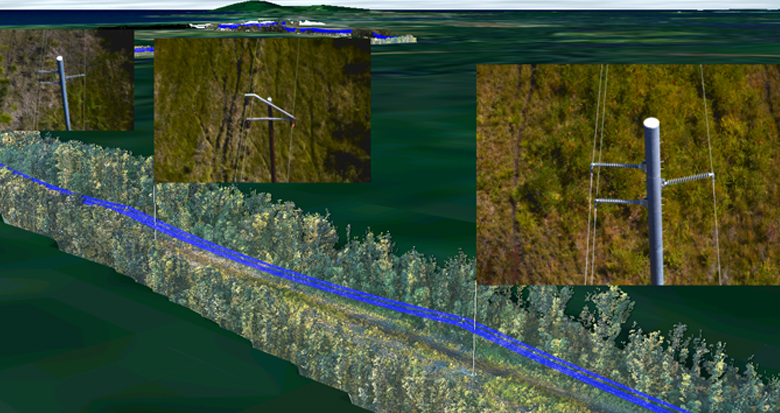

One of the additional benefits of LiDAR driven vegetation management programs is that ground clearances and line profiles can also be measured if specialist data analysis is undertaken. In addition, the data can be further used as a cost effective method to improve network positional data, such as pole locations. With the positional and spatial context of the network now being generated using remote sensing techniques it allows the linesman to concentrate on monitoring and maintaining the asset condition. This means foot patrols can be undertaken more efficiently focusing man hours on the high value tasks required in the field for a balanced overall cost.

The next chapter is to provide further efficiency savings by remotely collecting the condition data simultaneously to the positional data. The technology to achieve this is readily available but requires the right collection platform, sensor, and hardware configuration. When pulled together utilities benefit from condition reports for every asset scored by appropriate ‘risk’ levels along with high resolution imagery to visually verify from the desktop environment. These can be stored, maintained and called upon as historic condition records. Other options include infrared and UV sensors to determine other less visible defects. Having access to digital data means that more work can be done from the desktop, collaborating digitally with wider stakeholders and avoiding repeat trips to the field. Making this information more readily available helps to drive better operational decisions.

Does this remove the need for the man on the ground? - At the moment technology is at a point where it can’t answer all the condition questions. Pole rot, checking assets obscured by vegetation, or checking foundations will require a site visit for the foreseeable future. However, as the ground patrol becomes increasingly supplemented by technology solutions, the frequency of visits will vastly reduce the survey hours required in the field. As utilities demand better ways to understand their assets, it will be those solutions that can best harness position and condition data that will deliver the most effective productivity gains to the sector. This is an area where technology can play a meaningful part in driving down operating costs.