Delivering a critical PLS-CADD ratings project in under two weeks

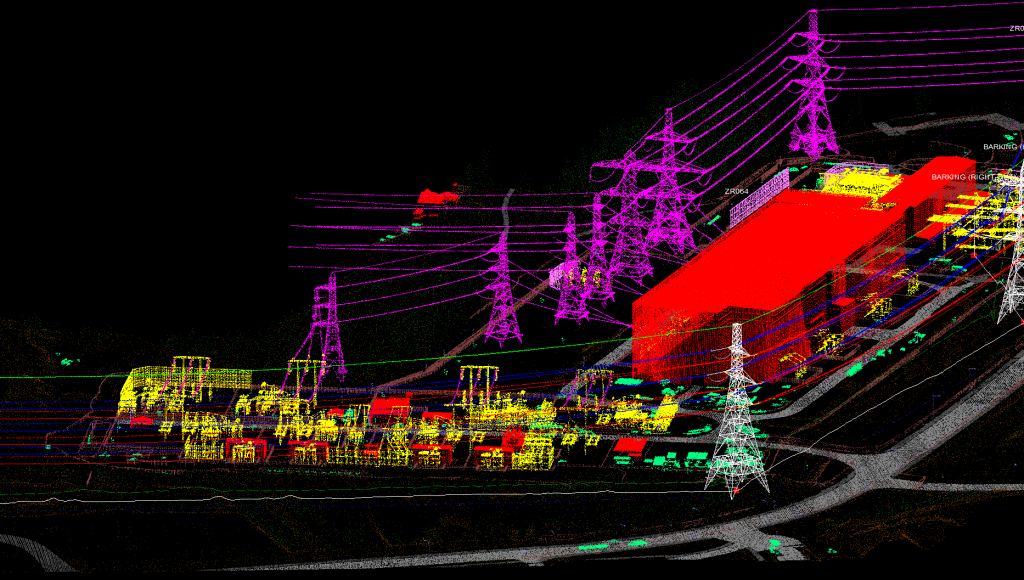

PLS-CADD modeling for ratings is the process of creating CAD models to enable a user to understand the constraints and/or to confirm compliance of a powerline circuit. Usually completed for transmission circuits is can nevertheless be used on distribution circuits, especially higher voltage lines.

Undertaking PLS-CADD modeling is a complex engineering-level process that takes a team of specialists to complete. This normally takes some time to finish. When you are looking at an end-to-end solution that comprises field data capture, data logistics, data processing as well as the detailed CAD process itself; then it is really no wonder it requires some time to deliver a high quality product.

The challenge

Recently though we were approached by a long time client who needed a critical project finished urgently in order to meet their internal deadlines. Could we model ten miles of transmission circuit in under two weeks? Our client had a problem that we could help with - so challenge accepted.

Field capture begins

Yes, the project was fairly small (just over 10 miles) but to even get aircraft off the ground requires a lot of work. Safety briefings, flight planning, field logistics, meteorological instruments need setting up to name just a few of the steps. Once the project was confirmed our field team lept into action. Capturing the project and checking data quality all in a single day. So far so good…

“What we did was create a new outlook for adapting work processes. We had to breakdown the individual components to find constraints and work out what was needed to further shorten processing time. This meant looking for any marginal gains that could be exploited. I look forward to applying a similar approach on future critical projects.” Kostas Lopsaitis, Head of Operations at NM Group

Data processing constraints

Due to NM Group’s experience in working on large scale PLS CADD jobs which are often time-sensitive we have been continuously refining the most effective approach to sequence the numerous data processing steps. This provides a proven way to deliver data quickly without sacrificing quality. But for this project we needed to go further.

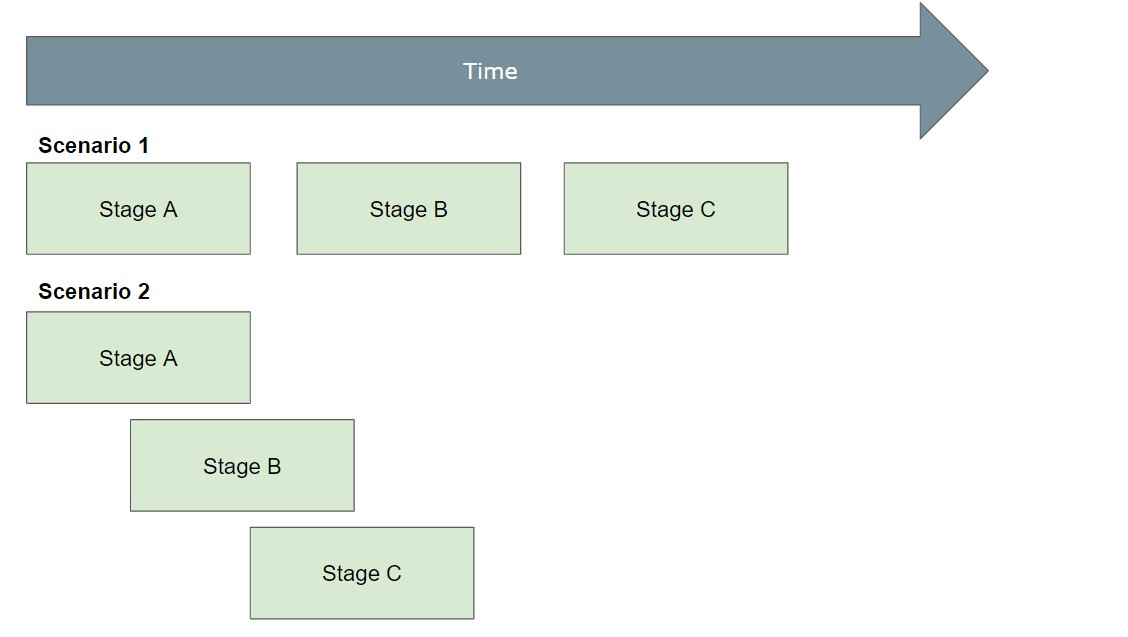

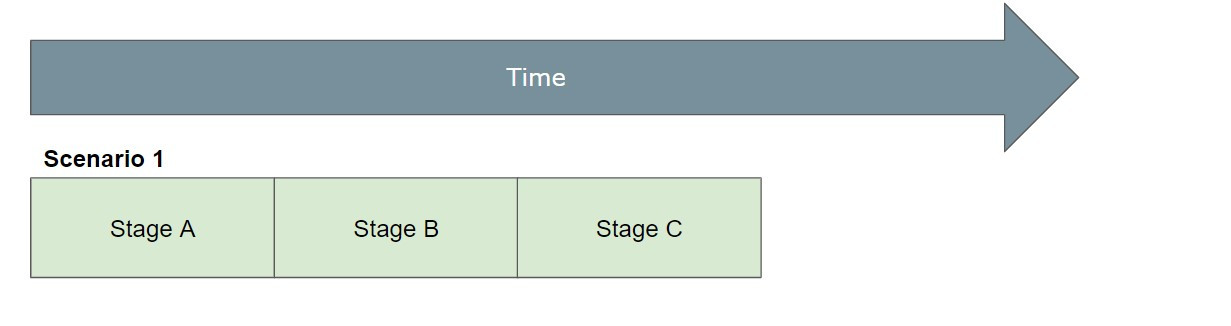

We’ve tapped into the Theory of Constraints and identified the most impactful constraints and bottlenecks we had in data processing resources. One of the fundamental challenges is the linear nature of doing some work. In a very basic sense, when work must follow Scenario 1 and individual process stages can only start when the previous stage is complete. This is typically longer than Scenario 2 where process stages can run with some overlap.

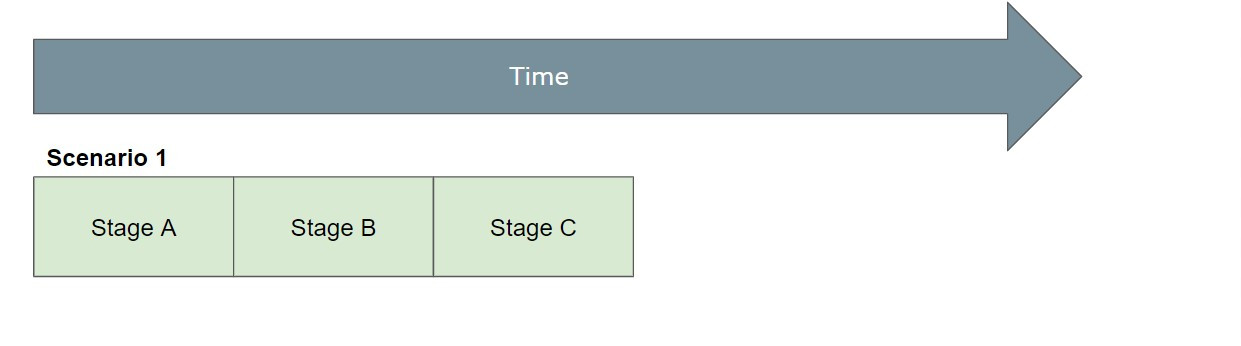

Even in tasks that can only be done using Scenario 1, time is frequently lost in gaps between stages (A to B, B to C and so on). We have rearranged our resources to enable us to have continuous production for critically urgent work. Effectively there is no waiting between completion of stage A and start of stage B.

We then looked at individual components of work in each stage and identified improvements (automation, better tools and training etc.) to truncate the time needed to achieve quality product.

Ultimately though, it required both Scenario 1 and 2 to really deliver time savings. This meant creating the best available process for individual work stages and overlapping multiple stages of production wherever possible.

The result

By carefully investing in further process improvements, finding efficiencies where possible and working tirelessly we were able to complete this project in eleven days. This is an expedited project, but shows what can be achieved with some outside the box thinking and a dedication to provide the best service possible. And the end result? A pleased client that could deliver to their internal deadlines.