Ask an Engineer – Part 3

What are the effects of emissivity and absorptivity when modeling power networks?

Let’s start by defining what emissivity and absorptivity are and considering how they affect conductor temperature. Emissivity is how much radiative heat will be emitted from an object. It varies from 0.0 where no heat is emitted, to 1.0 for an ‘ideal black body’ (a term coined by Gusthav Kirchhoff in 1860 to represent a physical body that absorbs all incident electromagnetic radiation). Absorptivity is the solar radiation that will be absorbed by a surface. Once more it varies from 0.0, meaning zero heat is absorbed, up to 1.0 for an ‘ideal black body’. Emissivity and absorptivity have relevance in three main areas:

The determination of conductor temperature from weather and electrical load

In our industry, conductor temperature determination is done to find the as-surveyed conductor temperature for a LiDAR survey. In the case of high solar radiation, the absorptivity will be important. If it is too high the conductor temperature will be higher than actual. Too low and the conductor temperature will be lower than actual. The most conservative approach is to err on the side of a higher absorptivity.

In the case of high conductor temperature, in comparison to ambient, the emissivity will be important. Should it be too high the conductor temperature determined will be lower than actual. Conversely, if it is too low the conductor temperature determined will be higher than actual. The most conservative approach here is to err on the side of a lower emissivity.

Thermal ratings calculation, from allowable temperature, weather data and electrical load

In these instances, a higher estimate of emissivity and absorptivity will mean that the solar gain will be increased (making the conductor hotter) and the radiative cooling will be increased (making the conductor cooler). Where the electrical load and solar gain effects are similar, these two factors will balance out. Where solar gain is not so much of a concern, the most conservative approach is to take a lower estimate of absorptivity and emissivity, giving less radiative cooling and thus lower allowable capacity for a given electrical load.

But be careful:

If you take a lower estimate of emissivity, you may be constraining your system un-necessarily. If you have a legitimate reason to continue with a higher emissivity value, go ahead, it is likely to yield significant additional capacity (around 5%).

IEEE-738 vs temperature determination from thermography (use of an IR camera)

In this instance, a higher estimate of emissivity will indicate a higher conductor temperature. If you are looking to determine the as-surveyed conductor temperature, it is likely that the higher emissivity will give the higher temperature and thus the most conservative approach.

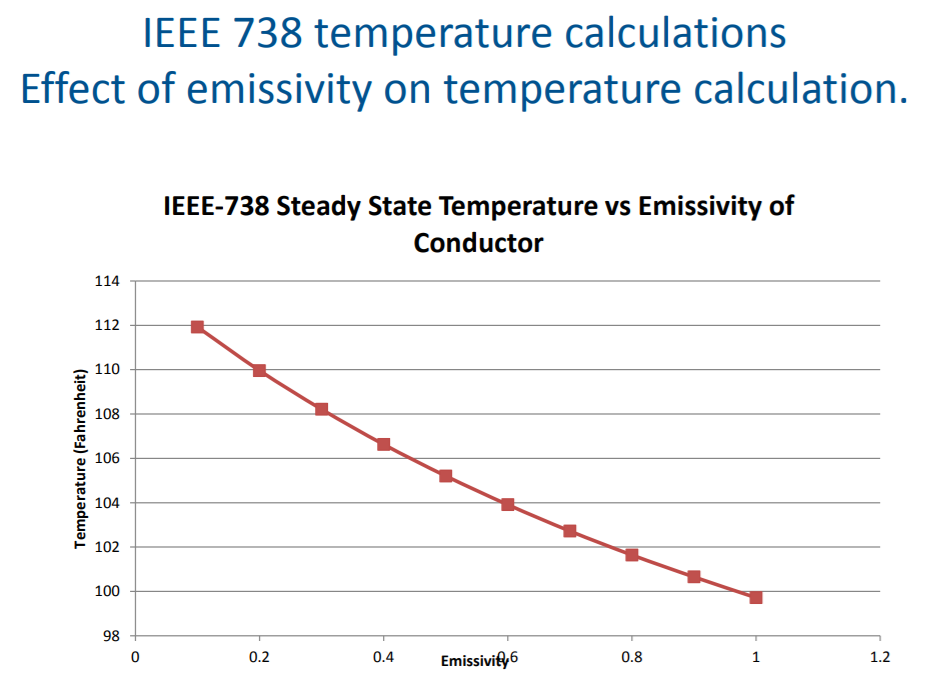

The effect of emissivity on IEEE-738 Conductor Temperature determination is quite small; in the example below an emissivity of 0.9 (fairly black) would reflect a temperature of 101 deg F, while an emissivity of 0.4 (pretty new) would reflect a temperature of 101 deg F. We are talking about a variance of around 5 degrees. This is a nice buffer / increased rating as long as there are sufficient grounds to justify it.

Again, be careful:

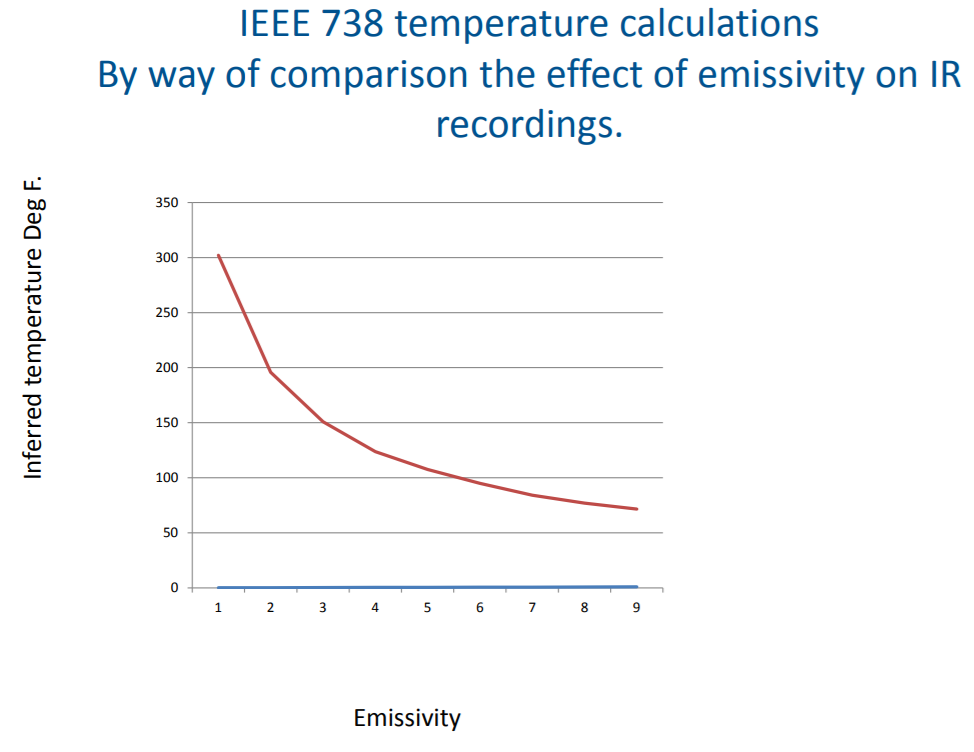

If we model the effect of emissivity change on temperature using thermography, it has a huge impact. For an emissivity of 0.9 we can estimate a conductor temperature of 75 deg F, while for an emissivity of 0.4 we would estimate a conductor temperature of 125 deg F. An uncertainty in temperature determination of 50 deg F.

Conclusion

The effect of emissivity and absorption are important in creating an accurate model. How important though, really depends on other factors. The environmental context plays an important role here and it requires engineering understanding when applying this to powerline modeling. In particular, make sure you are fully aware of the effect of emissivity when using IR measurements as this can have a much more profound effect on the uncertainty in temperature determination.

As Director of Engineering and heading up research and development at NM Group, Paul Richardson is a renowned power industry expert and long-time proponent of the use of 3D modeling in improving reliability and utilization, while minimizing cost. He is a chartered civil engineer (BEng Hons, CEng, MICE), and retains a wealth of experience, including more than 20 years of power line engineering.

If you've missed any previous editions of Ask an Engineer, you can read them all here.